Transmission Clutch Basics

All Jeeps with Manual Transmission

Inside every manual transmission vehicle is a nifty little component called the clutch. It is usually not considered until the driver fears it is “burned-out,” typically while trying to get their ride unstuck from the mud or snow, the clutch is every bit as important as the engine and the transmission. Located between the engine and transmission in a bell-shaped housing cleverly known as the bellhousing, the clutch is actually a complex system of moving parts that, when engaged, work to disengage the power to the drivetrain. Without the clutch acting as a middleman between the engine’s power and the transmission’s gears, it would be next to impossible to start, stop or shift gears without grinding them or lurching the vehicle to an unpleasant and embarrassing stop. When disengaged, the output shaft from the transmission is again inserted into the clutch disc to allow the engine to turn the shaft and deliver power to the wheels.

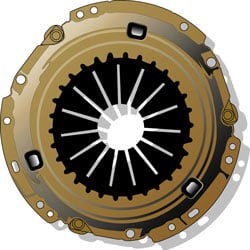

Pressure Plate: The pressure plate assembly is secured to the flywheel via bolts connecting the cover stamping to the flywheel. During engagement, the pressure plate assembly clamps the disc assembly against the flywheel, transmitting engine power to the transmission. During disengagement, power flow is interrupted when the pressure plate no longer clamps the disc against the flywheel. Instead, the pressure plate lifts away from the flywheel, creating a gap large enough for the disc to disengage from the flywheel, enabling the driver to shift gears.

Pressure Plate: The pressure plate assembly is secured to the flywheel via bolts connecting the cover stamping to the flywheel. During engagement, the pressure plate assembly clamps the disc assembly against the flywheel, transmitting engine power to the transmission. During disengagement, power flow is interrupted when the pressure plate no longer clamps the disc against the flywheel. Instead, the pressure plate lifts away from the flywheel, creating a gap large enough for the disc to disengage from the flywheel, enabling the driver to shift gears.

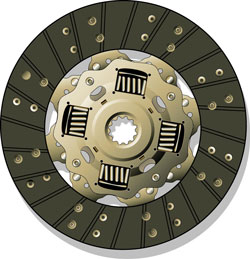

Clutch Disc: The disc assembly is mounted to the input shaft, between the pressure plate assembly and the flywheel. During engagement, the disc slides forward on the input shaft and becomes solidly clamped, or “engaged”, between the flywheel and the pressure plate assembly. During disengagement, when the driver presses the clutch pedal, the disc is separated from the flywheel to allow the driver to change gears. Although the pressure plate assembly and flywheel continue rotating, the input shaft and disc are no longer being rotated by the engine.

Pilot Bushings: Pilot bearings and bushings serve as a guide and seat for the transmission input shaft during engagement and disengagement when the flywheel and pressure plate assembly turn at speeds different than the input shaft and disc assembly. A properly-functioning pilot bushing will allow the flywheel to maintain the RPM of the engine while also allowing the input shaft to slow down, either when changing gear or coming to a stop.

Throw-out Bearing: Release bearings are designed to pivot forward and compress the pressure plate levers, which disengages the clutch system. Although release bearings are all designed for the same basic function, they come in many shapes and sizes because they must work in conjunction with a variety of actuation systems.

For example, angular contact bearings are matched with hydraulic systems,  and are designed to remain in “constant contact” with the clutch diaphragm spring fingers. As a result, these bearings utilize a self-centering feature that compensates for misalignment by centering the bearing equally on the diameter of the diaphragm spring fingers. This reduces noise, heat, vibration, and bearing wear while increasing the life of the clutch system.

and are designed to remain in “constant contact” with the clutch diaphragm spring fingers. As a result, these bearings utilize a self-centering feature that compensates for misalignment by centering the bearing equally on the diameter of the diaphragm spring fingers. This reduces noise, heat, vibration, and bearing wear while increasing the life of the clutch system.

Standard release bearings, by comparison, aren’t designed for constant contact applications. Instead, they  are engineered to work in conjunction with mechanical actuation systems because the release bearing thrust face is in contact with the pressure plate fingers only during clutch actuation. Contact time is so short that slight misalignment isn’t a factor.

are engineered to work in conjunction with mechanical actuation systems because the release bearing thrust face is in contact with the pressure plate fingers only during clutch actuation. Contact time is so short that slight misalignment isn’t a factor.

The most recent change in release bearing technology is to integrate the clutch actuation systems and released bearing into one component. This system is referred to as a CSC (concentric slave cylinder). It eliminates the need for several additional components including the fork, bearing retainer, pivot ball, and traditional style release bearing.